Unternehmen

KWST offers its entire product line from its own production for a wide range of applications.

Over 60 experts in production, development, sales and service ensure that customers are advised and served flexibly, competently, quickly and punctually “around the clock”.

We work and operate according to a philosophy that is characterized by fairness, reliability and sustainability. In this way, we achieve long-term positive results in our production and distribution of various ethanol products. The fact that we act sustainably is confirmed not least by various certificates from independent institutions.

History

Corporate philosophy

Our actions and conduct are intended to preserve an intact environment and foster peaceful and prosperous cooperation of all human beings throughout the world, Europe, Germany, Lower Saxony, and in our immediate neighborhood.

Against this backdrop, we have developed a mission statement for our business conduct that is based on fairness, reliability and sustainability .

We seek to follow these three principles in our daily lives and our business transactions.

Human rights, the German constitution (or “Basic Law”), our Christian values and moral principles are the standards by which we are measured.

In this sense, we are committed to:

We feel an obligation towards our environment and fellow human beings, in particular, however, towards our employees, customers, shareholders, suppliers and partners.

Production

In 5 continuously operating distillation plants, on more than 330 days out of the year we produce highly purified neutral alcohol from grain, sugar beets and sugar cane. With a capacity of over 80,000 m³, we are among Germany’s largest producers of industrial alcohol.

We in large part developed the plants on our own and build them with competent partners from the region. This allows us to ensure that our standards for sustainable and highly-efficient production can be fulfilled. In production this means for us:

In order to ensure and continually improve upon the high standard in production, at KWST, special emphasis is placed on initial and further training of employees. A high level of expertise is one of the critical success factors for the company.

The key production facilities are located at the Misburg site:

Rectification and dehydration

Wastewater recovery and recycling

Ethanol and molasses storage

Loading and denaturing facilities

Certification

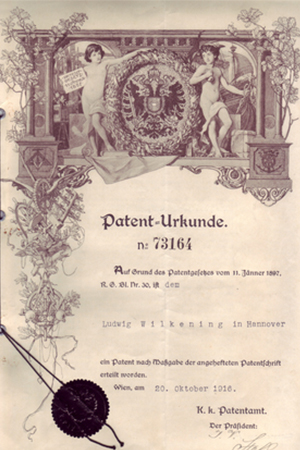

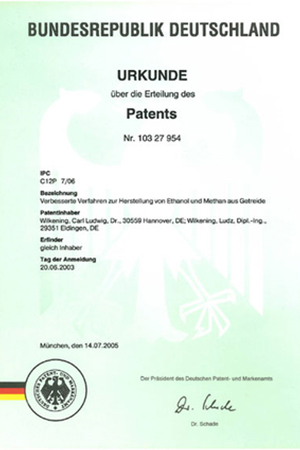

In its long history, KWST has gained substantial experience on the topic of sustainability. Since the 19th Century, the company has been producing bioethanol with high efficiency on the basis of renewable raw materials and a highly-favorable CO2 balance. Power of innovation is one of our company’s key assets and has enabled us to continually expand ethanol production over several decades. Not least, this results in decisive advantages for our customers, which is also reflected in various certificates:

Based on the requirements of the “Codex Alimentarius” and the key statutory regulations, our production continuously undergoes testing according to an HACCP study.

By involving all employees in the further development of the processes relevant to quality, we are constantly advancing our continuous improvement processes according to the theme, “achieving greater quality together”.

1856

1856  1870

1870  1916

1916  1918

1918  1945

1945  1950

1950  1978

1978  1980

1980  1983

1983  1984

1984  2001

2001  2004

2004  2004

2004  2005

2005  2007

2007  2009

2009  2011

2011  2012

2012  2014

2014